LPOne covers the entire routing process, from planning/cost evaluation to the actual cost of activities, via cost analysis and warehouse availability analysis.

As a management approach, Lean Production focuses on eliminating wastage across the entire production supply chain, directing managerial decisions towards the identification of processes that actually add value.

LPOne is an organic and comprehensive approach to production, with the aim of reducing waste wherever possible and of whatever nature, thereby containing costs and at the same time improving the quality, speed and efficiency of a company's production system.

The context and the approach

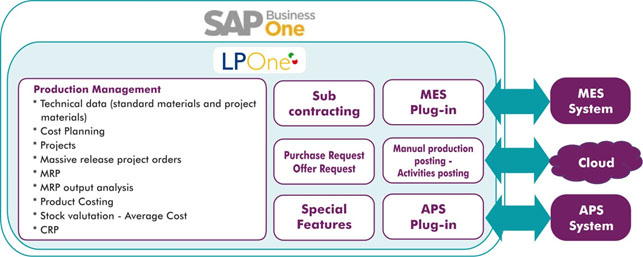

LPOne is completely integrated within SAP Business One, as SAP Business One Integration certification certifies on an international scale. LPOne uses standard SAP procedures, possibly extending them and enhancing them with additional functions and components.

For instance, Materials Master Data, Bills of Materials and Production and Purchase Orders are the standard SAP Business One ones, enhanced with the necessary data for LPOne, whereas brand new Work Centers, Processing Phases and Routings Master Data have been implemented.

For MRP, Product Cost Evaluation and Project Management, new functions proprietary to LPOne have been implemented to exploit its full potential.

All the functions and structures of LPOne have been developed in strict compliance with SAP standards, to guarantee both operation and maintenance, as well as any upgrades over time.

LPOne conforms to both the standards envisaged by Microsoft SQL Server as well as those of SAP HANA.

Functional coverage and commercial positioning

LPOne consists of a series of modules, as shown in the diagram, which group together functions which cover specific areas, typically linked to production processes.